Key Takeaways

- Advanced materials like polyurethane and composites are enhancing caster durability and floor protection.

- Ergonomic designs and noise-reduction technologies are improving workplace safety and comfort.

- Integration of innovative technologies enables real-time monitoring and predictive maintenance.

- Sustainable practices in caster manufacturing are reducing environmental impact.

Table of Contents

- Introduction

- Advanced Materials Enhancing Durability

- Ergonomic Designs for Improved Safety

- Smart Technologies in Caster Wheels

- Sustainable Practices in Manufacturing

- Customization for Industry-Specific Needs

Introduction

The evolution of casters and wheels is reshaping material handling across industries, unlocking new levels of efficiency and adaptability. Whether manufacturing, logistics, or healthcare, the latest advancements in wheel and caster technology are driving safer, greener, and more productive workplaces. A significant improvement in this space includes innovations in phenolic caster wheels, which balance strength, resilience, and maneuverability, making them a trusted solution for moving heavy loads without damaging floors.

Material handling operations depend heavily on the reliability and versatility of their transport equipment. As casters and wheels integrate more intelligent systems and tougher materials, companies are experiencing fewer disruptions and lower costs from maintenance and replacements. The move toward phenolic caster wheels and other advanced types is just one example of how focused innovation simplifies complex, high-stakes environments.

Advanced Materials Enhancing Durability

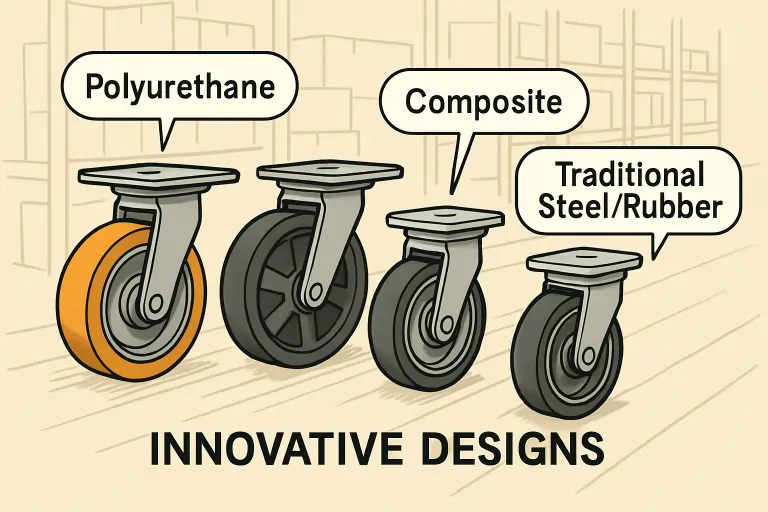

The choice of materials is vital in caster and wheel design. Traditional steel or rubber wheels are now replaced or supplemented by advanced materials like polyurethane and composites. Polyurethane, in particular, offers flexibility and toughness, reducing the risk of floor scarring and extending the life of both the wheels and the surfaces they travel on. Its high load-bearing capacity is perfect for warehouses and manufacturing environments where longevity and dependability are mandatory.

Additionally, composite wheels provide a superior strength-to-weight ratio, resulting in lighter equipment that demands less energy, even under heavy loads. This not only boosts productivity by making carts and racks easier to push and pull but also contributes to decreased workplace injuries. As Forbes highlighted, the role of materials innovation is growing rapidly, enabling businesses to keep pace with fast-changing operational demands.

Ergonomic Designs for Improved Safety

Material handling tasks are a leading cause of workplace injuries, making ergonomics a top priority for equipment manufacturers. Modern caster designs feature advanced swivel and locking mechanisms, shock-absorbing features, and noise-reducing treads. These innovations simplify maneuvering heavy loads around tight spaces and rough surfaces, dramatically decreasing the physical strain on operators. Ergonomic improvements not only contribute to worker comfort but also result in improved morale and operational uptime.

User-focused enhancements, such as easy-to-engage brakes and dual-wheel designs, provide greater control and stability when handling valuable or fragile items. This is especially crucial in hospitals or laboratories, where accidental drops or spills can be costly or dangerous. By upgrading to ergonomic casters, organizations reduce absenteeism and support sustainability by extending the equipment lifecycle by reducing preventable damage.

Smart Technologies in Caster Wheels

The digital transformation of material handling is well underway. Smart casters now incorporate IoT-enabled sensors that track movement, monitor load weight, and measure wheel wear in real time. Data is transmitted to central dashboards, enabling predictive maintenance and reducing the risk of unexpected breakdowns. According to Vizai Engineering, these innovative technologies allow proactive servicing, helping companies minimize downtime and optimize asset management.

With predictive analytics, companies can schedule repairs or replacements before failures occur, supporting continuous operations and lowering total lifecycle costs. Larger organizations that manage extensive fleets of carts or dollies are especially poised to benefit, as connected casters provide critical insights into performance trends and operational bottlenecks.

Sustainable Practices in Manufacturing

Sustainability is becoming a core focus for material handling equipment manufacturers. Companies are reducing their environmental impact by adopting recycled and recyclable materials in caster production and implementing energy-efficient manufacturing processes. The movement toward a circular economy encourages manufacturers to design wheels and casters for easier reuse, refurbishment, or recycling after their primary service life.

Both regulatory pressure and a genuine commitment to environmental stewardship drive these changes. For example, many leading manufacturers are working to comply with global sustainability standards and certifications. Sustainable caster solutions provide an eco-friendly option that doesn’t compromise on performance, aligning with the goals of organizations aiming to meet their corporate social responsibility targets.

Customization for Industry-Specific Needs

Different industries require unique solutions for their daily operations, which is why customization is rapidly gaining traction in caster and wheel development. In healthcare, casters with antimicrobial coatings are standard, helping maintain high hygiene levels in sensitive environments. Meanwhile, e-commerce and distribution centers rely on specially designed wheels and casters to withstand high volumes and constant movement across various surfaces.

Tailored caster products also support specialized applications, such as high-temperature environments in food processing plants or anti-static uses in electronics manufacturing. By choosing components specifically suited to their operating conditions, organizations can optimize productivity, prevent equipment failures, and enhance overall workplace safety.

In summary, the relentless advance of caster and wheel technology redefines material handling for modern industries. From resource-saving design to ergonomic engineering and data-driven improvements, investing in the right caster solutions delivers a competitive edge while improving safety, efficiency, and sustainability in every environment.

Also Read- Smart Home, 21st Century Comfort: Should You Bring Tech into Every Corner?