In textile printing, technology keeps evolving to balance cost, quality, and efficiency. Direct-to-Film (DTF) printing has emerged as a solution that delivers on all three. For businesses still weighing options between traditional techniques and newer digital solutions, it helps to learn more about how DTF compares with screen printing. This context is important before diving deeper into the working principle and core technology that make DTF printers a reliable choice.

Understanding the Working Principle of DTF Printers:

At its core, a DTF printer operates by transferring designs directly onto a special PET film, which is then heat-pressed onto fabrics. Unlike sublimation or screen printing, DTF technology bypasses many limitations, offering compatibility with a wide variety of materials and colors.

Step-by-Step Printing Process:

- Digital Design Preparation

The process begins with the creation of a digital design using graphic software. This ensures precision and allows for unlimited customization, whether for small runs or bulk orders. - Printing onto PET Film

The design is printed onto PET film using specialized pigment inks. These inks are formulated to deliver vibrant colors and sharp details. - Application of Adhesive Powder

Once the design is printed, an adhesive powder is applied to the wet ink. This powder plays a crucial role in ensuring durability and strong adhesion when the design is later transferred. - Curing Process

The film, now coated with powder, is passed through a curing oven. This process melts the adhesive powder, binding it with the ink and preparing it for transfer. - Heat Transfer to Fabric

Using a heat press machine, the cured film is applied to fabric at a set temperature and pressure. The result is a permanent, high-quality print with excellent wash resistance.

This straightforward yet effective working principle makes DTF printing accessible for both large-scale printing shops and small businesses.

Core Technologies Driving DTF Printers:

While the workflow of DTF printing may appear simple, the technology that enables it is highly advanced. Let’s explore the core technologies that make DTF printers a powerful solution:

1. Advanced Ink Technology:

DTF inks are water-based pigment inks specifically engineered to bond with multiple types of fabrics. Unlike sublimation inks that work primarily on polyester, DTF inks provide vibrant and durable results on cotton, polyester, blends, and more.

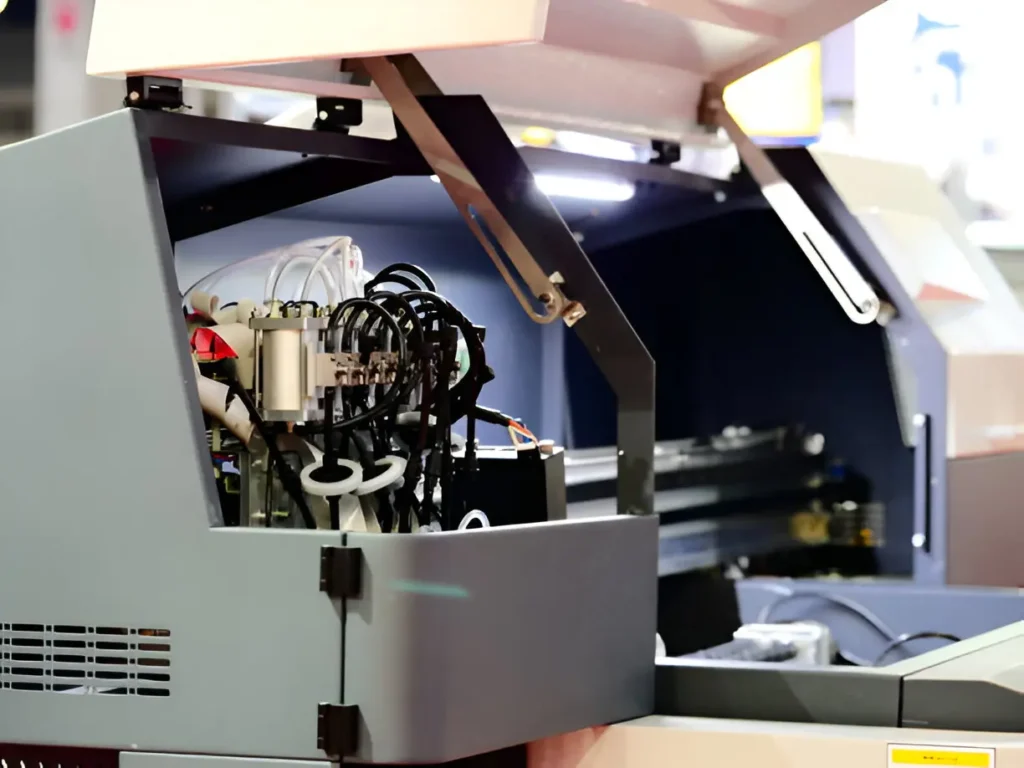

2. Precision Print Heads:

The print head is the heart of any DTF printer. Equipped with micro piezoelectric technology, these print heads ensure fine droplet placement, producing high-resolution images that retain detail and color accuracy even on complex designs.

3. PET Film Coating:

The specialized PET films used in DTF printing are coated to accept ink precisely. This coating allows for crisp, smudge-free designs that are easy to handle during transfer.

4. Adhesive Powder Application Systems:

Automatic powder-shaking and curing systems streamline the process by evenly distributing adhesive powder and ensuring consistent curing. This reduces manual effort and increases overall productivity.

5. Heat Transfer Precision:

Modern DTF printers work hand-in-hand with efficient heat presses that guarantee consistent temperature and pressure, critical for achieving professional-grade results.

Benefits of DTF Core Technology:

The integration of these technologies gives DTF printers several significant advantages:

- Versatility: Ability to print on cotton, polyester, silk, blends, and even non-textile items like bags or caps.

- Durability: Prints are resistant to washing, cracking, and fading.

- Efficiency: Faster turnaround times compared to screen printing, especially for smaller batches.

- Cost-Effectiveness: Lower setup costs make it ideal for both large orders and one-off customized designs.

- Scalability: Businesses can start small and scale up with ease as demand increases.

Comparison with Traditional Printing Methods:

To fully appreciate DTF technology, it’s worth comparing it with alternatives:

- Screen Printing: While excellent for bulk production, it requires significant setup, more labor, and lacks the flexibility of DTF.

- Heat Transfer Vinyl (HTV): Limited to simpler designs and often less durable.

- Sublimation: Produces stunning results but works only on light-colored polyester fabrics.

In contrast, DTF printing offers a balanced solution that combines flexibility, cost savings, and quality.

Real-World Application and Industry Adoption:

Many print shops and fashion businesses are embracing DTF technology because it bridges the gap between affordability and quality. The ability to take on both custom single orders and large-scale production runs means greater business opportunities and improved profitability.

Midway through this growth, brands such as DTF LINKO are gaining recognition for providing cutting-edge printers and consumables that improve consistency and performance. By investing in such reliable technology, businesses can maximize efficiency and reduce downtime.

Long-Term Potential of DTF Printing:

The trajectory of DTF technology suggests strong long-term potential. As ink formulations improve, films become more eco-friendly, and machines become even more efficient, the benefits of DTF will only grow. Moreover, as consumer demand for personalized, high-quality products rises, DTF printers are uniquely positioned to meet those expectations.

Conclusion:

The analysis of the working principle and core technology of DTF printers highlights why this printing method is revolutionizing the industry. Its straightforward process, powered by advanced ink chemistry, precision print heads, and durable consumables, ensures a combination of cost-efficiency and quality that few alternatives can match.

For businesses aiming to grow in the competitive textile printing market, adopting DTF technology is not just an upgrade—it’s a strategic move. By understanding its principles and leveraging its core technologies, companies can unlock new opportunities, serve diverse customer needs, and secure long-term profitability.

Also Read-Staying Ahead in Dental Practice: Continuous Education, Tech Trends, and Patient Care